Inventory control is the process of tracking stock levels while monitoring customer demand. This allows businesses to ensure they have the products people want at the time in the correct quantities. The quantities part is the most important because it helps businesses avoid over or understocking a certain product. Knowing the quantities of products also helped prevent theft and damage. Having the right stock at the right time means businesses adequately manage their supply chains and customer service operations. All this improves efficiency and profitability.

What Is Inventory Control?

Inventory control, also called stock control, is the process of ensuring the right amount of supply is available in an organisation. With the appropriate internal and production controls, the practice ensures the company can meet customer demand and delivers financial elasticity.

Successful inventory control requires data from purchases, reorders, shipping, warehousing, storage, receiving, customer satisfaction, loss prevention and turnover.

Inventory control enables the maximum amount of profit from the least amount of investment in stock without affecting customer satisfaction. Done right, it allows companies to assess their current state concerning assets, account balances and financial reports. Inventory control can help avoid problems, such as out-of-stock (stockout) events. For example, Walmart estimated it missed out on $3 billion worth of sales in 2014 because its inadequate inventory control procedures led to stockouts.

An integral part of inventory control is supply chain management (SCM), which manages the flow of raw materials, goods and services to the point where the company or customers consume the goods. Warehouse management also squarely falls into the arena of stock control. This process includes integrating product coding, reorder points and reports, all product details, inventory lists and counts and methods for selling or storing. Warehouse management then synchronises sales and purchases to the stock on hand.

Inventory management is a higher-level term that encompasses the complete process of procuring, storing, and making a profit from your merchandise or services. While inventory control and inventory management may seem interchangeable, they are not. Inventory control regulates what is already in the warehouse. Inventory management is broader and regulates everything from what is in the warehouse to how a business gets the product there and the item’s final destination.

Inventory control practices and policies should apply to more than just finished and raw goods. The following graphic shows all the things a business might manage using these practices.

The Reach of Inventory Control: Beyond Finished and Raw Goods

Why Is Inventory Control Important?

Inventory is one of the biggest costs of capital of any product-based business. If you look at the balance sheet of this type of company, you’re likely to find that inventory makes up a large portion of current assets and uses up a lot of working capital.

Inventory control helps avoid the many costs related with buying too much inventory and the strains of going without the needed inventory. While some companies using just-in-time ordering may carry extremely small inventories, nearly any business requires some form of inventory, which is best managed through inventory control systems.

If a company can lower inventory, it may find new funds available for expansion or profits. If a company needs to carry more inventory and tight inventory control processes bring inventory levels up, the business could find higher sales, and again higher profits. Using inventory control to optimise your warehouse, stock room, supply room, or storefront is a sure way to cut costs and better manage any kind of product.

How Inventory Control Can Improve Your Business

Implementing proper inventory control procedures can help ensure a business is running at optimal financial levels and that products meet customers’ needs and expectations. According to the 2015 “Global State of Multichannel Customer Service Report”, 62% of customers have stopped doing business with a brand whose customer service was poor. Of those customer service complaints, frustration over out-of-stock or backordered items is high on the list.

In fact, research about convenience stores shows that out-of-stocks could cause a store to lose one in every 100 customers completely. Additionally, 55% of shoppers in any store would not purchase an alternate item when their regular product is out-of-stock. Other areas where businesses incur expenses or lose sales that inventory control practices and methods could address include:

- Spoilage

- Dead stock

- Excess storage costs

- Cost-efficiency

- Decreased sales

- Losing loyal customers

- Excess stock

- Losing track of inventory

- Losing goods in the warehouse

According to professor and author David Pyke, “Owners of small and emerging businesses would be stunned to see how much help they can get and money they can save by wisely managing their inventory. Many small businesses are not rolling in cash, and much of their funding is tied up in their inventory. Good practices balance customer demand and management of inventory in the smartest possible ways.”

4 Ways to Control Inventory

At its core, taking stock is just the process of determining what you have and where you store it so that you can evaluate it. Not all warehouse control procedures are ideal for every business or for the varying stages of an organisation’s growth and development. Some methods are too complicated, especially for smaller companies.

You should be able to use your system to track inventory levels, create orders and send out stock. Some basic systems for tracking inventory include:

Manual: Whether via a ledger or a stock book, manually logging inventory with a pen and paper is the simplest way to track what comes in and goes out. Small businesses with few items can get away with using this type of system. This system can be challenging because it is an actual record that you cannot mine and use for planning purposes.

Stock Cards: A slightly more complex method uses stock cards, also called bin cards. A stock card is a table that records the running unit price, sale price and inventory count of each product. Use individual cards for each product in large warehouses or stock rooms. The system also tracks purchases, sales, returns and other reasons to withdraw stock, such as promotional withdrawals. You can include additional notes on the stock card, such as any problems associated with that item. For a stock card system to be effective, consistent updates are critical. You must also record unusual stock pulls; otherwise, you run the risk of inaccurate data.

Simple Spreadsheets: Many companies, especially small businesses, use spreadsheets to track inventory. Whether they use Microsoft Excel or something similar, spreadsheets are a way to start automating and electronically capturing product data. With consistent updating and basic coding, you can ensure that you have available current stock levels and statistics. Businesses quickly customise these systems to meet their needs. Since everyone who builds a spreadsheet does so slightly differently, users will need intimate knowledge of how the sheet works. This method is also thought of as manual because the only way to automatically update the spreadsheet system is by adding high-level macros or coding that connects them with other systems.

Basic Inventory Software: Simple inventory software is usually low cost and targeted to small and medium-sized businesses. This simple automation is often cloud-based and ties into your point of sale software, so it can generate real-time, automatic stock updates. You can also incorporate analytics and reporting and run cost comparisons, create reorders, identify best and worst-selling products and drill down to order details or customer patterns. Some simple inventory management software systems can scale to more complex functionality as your business grows.

Some businesses prefer to stick to the simple systems of keeping track of inventory. Other companies plan for growth and scaling. You could also track inventory with:

- Advanced Software: Designed for tracking inventory, most of these targeted software solutions can integrate with existing software, are scalable and provide analytics and templates. Advanced software is now in reach for many small and midsize businesses because it is no longer cost prohibitive.

Types of Inventory Control Systems

Inventory control and monitoring systems are accounting approaches to track the number of goods on hand. Big companies often monitor inventory across stores, warehouses and even websites. The two main systems are periodic and perpetual tracking systems.

The Periodic System vs. the Perpetual System

The Periodic Inventory System

Most small businesses still use periodic inventory management because it does not require sophisticated software or inventory scanning. A periodic inventory system relies upon occasional or regular physical counts of the inventory. You decide accounting periods based on the business needs, but you don’t track inventory daily or continuously. Instead, you record all purchases to a purchase account. Once you conduct the physical inventory, you shift the balance in the purchase account into the inventory account. Finally, you adjust the inventory account to match the cost of the ending stock. You can calculate the cost of ending inventory using either FIFO (first in, first out) or LIFO (last in, first out).

The challenges of the periodic system are especially apparent when performing a physical inventory count. Most normal business activities must be suspended during this time because it requires significant manual labour. Many companies hire additional staff and try to perform this outside of regular business hours, such as during a night shift. This type of system incurs more fraud because there is nothing tracking inventory between physical counts, reducing accountability between inventories, and because it is more challenging to determine where any inventory discrepancies occurred.

The Perpetual Inventory System

The perpetual system may be more expensive to implement than the periodic system due to equipment and software needs. However, the system continuously and immediately updates inventory numbers. This system calculates inventory based on sales and purchases via the point of sale and asset management software. This way, you have accurate stock on-hand accounting at all times. Perpetual tracking is the best way to avoid stockouts when your customers deplete inventory on a particular product. With a perpetual system, you can achieve minimal employee contact with the goods.

The challenges of this type of system occur when you use it without also performing physical inventories. In other words, the recorded inventory may not accurately reflect what is physically in-stock as time goes by, never mind accounting for drop shipments or inventory on order. You must account for breakage, stolen goods and loss to ensure the system is accurate. Further, errors and improperly scanned items affect the inventory records. You can handle this mathematically by applying corrections that mostly account for these things. Experts agree, though, that even though physical inventories are not common, you should implement some manual stock taking process to complement a perpetual system. You can integrate these types of systems with supply-chain automation to make quicker decisions informed by data.

Barcodes

Barcodes can be part of either a perpetual or periodic inventory system. Some may consider the barcodes part of an inventory management system, but in truth, this is equipment that falls under your existing stock management system. A barcode is essentially a little picture with text or numbers that gets put on each stock item. The text or numbers store a large amount of information. A scanner reads that information and transfers it to a database, which tracks the parts and their locations. The system performs scans when the new product arrives and when it is issued out. Barcodes have a rapid return on investment (ROI) by lowering operating expenses once implemented, even for small businesses(opens in a new tab).

Other benefits of barcoding include:

- The elimination of manual data errors

- Faster collection of inventory information

- Automatic inventory updates

- Streamlining of documentation and reporting

- Enabling inventory movement between multiple warehouses and departments

- Easy and quick identification of minimum levels and reordering of necessary levels

Implementing barcodes on inventory is a smart idea because they offer scalability and accuracy, even to small and growing businesses.

Radio Frequency Identification (RFID)

RFID tags are also a type of equipment that falls under an existing inventory management system. RFID tags are a type of smart tracking. RFID tags contain electronically stored information, more information than is possible with conventional barcodes. Tags can be passive or active: Active RFID tags include batteries, whereas passive tags do not have batteries. The RFID reader supplies the power for passive tags through radio waves, whereas active tags send out their radio waves. Both types of tags automatically update to identify the stock and capture any associated data.

RFID tags are an effective way to protect high-value items and products that require additional security compliance, such as pharmaceuticals. Active tags are the best course in businesses where inventory security has been an issue.

Although security is the primary benefit of RFID, other features include:

- Remote Tag Reading: The reading range for passive tags is approximately 40 feet, and the range for active tags is 300 feet.

- Simultaneous Tag Reading: The system can read several tags simultaneously so that it can check in an entire pallet of products at once.

- Unique Tag Codes: To track unique products, not just one type of product, you can give tags unique identification codes.

- Constant Updates: Without having to update the physical tag on the item, you can send it updates such as warehouse location via your active tag or by keeping the passive tag system activated.

Some challenges with using RFIDs include:

- Passive RFID tags require scanners or handheld readers.

- The cost can be prohibitive for some businesses.

- The supply chain also needs the equipment necessary for RFID tags.

If you are considering using RFID tags, they have become cheaper in recent years. Experts say the best use of RFID tags is to place them at high-risk points close to your stock, such as at exits. Finally, for products with a limited shelf life, an RFID system can provide information to ensure quality control, such as when they were brought in and their expiration dates (if relevant).

A recent trend among small businesses is the use of QR codes, which are like barcodes, but you don’t need to buy expensive equipment to read them. You can install an app on a smartphone that reads QR codes. They also carry more information than a barcode because of their matrix-like patterns. QR codes are not active systems like active RFID tags and not nearly as expensive.

Inventory Control Methods

Inventory control methods are the ways you use your business’s strengths and relationships, your expertise, formulas and forecasts to determine how much supply you keep, sell, store and order. Effective inventory control balances controlling costs and meeting customer demands.

A company’s days of inventory outstanding (DIO) measures how many days a company holds stock before selling it. The DIO is an efficiency measure because product stock ties up funds. The lower the DIO the better, especially for a small business. DIO scores have increased in the past five years by 8.3%(opens in a new tab), meaning that companies have poorer inventory control practices. Additionally, there is a need to increase warehouse space, which means additional costs for businesses. This trend underscores the importance of optimising inventory control to reduce the duration goods remain in stock, thereby minimising capital tied up in inventory and the associated storage costs.

The Correlation Between DIO and Warehouse Space

8 Inventory Control Techniques

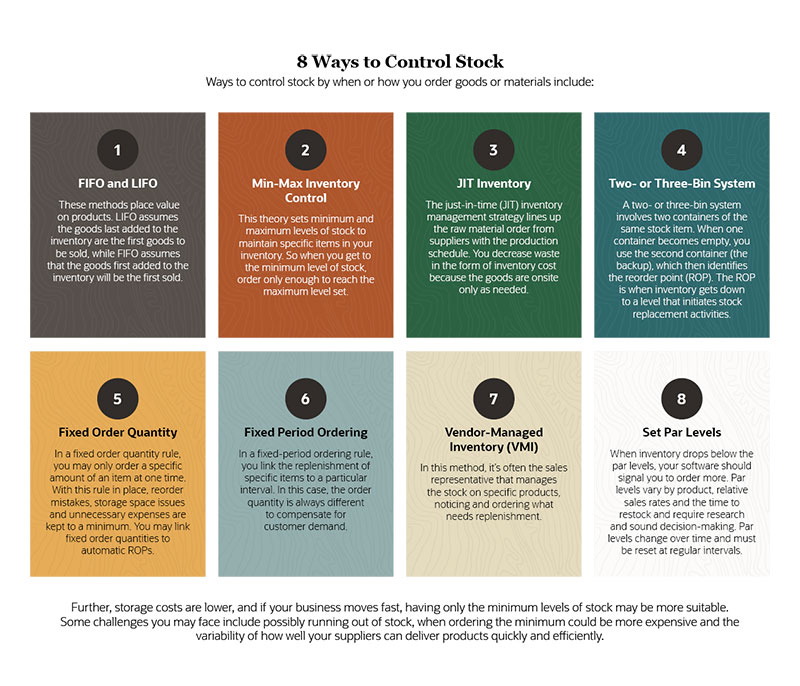

Ways to control stock by when or how you order goods or materials include:

FIFO and LIFO: These are methods of placing value on the products. LIFO assumes that the goods last added to the inventory are the first goods to be sold, while FIFO assumes that the goods first added to the inventory will be the first sold.

Min-Max Inventory Control: This theory sets minimum and maximum levels of stock to maintain specific items in your inventory. So, when you get to the minimum level of stock, order only enough to reach the maximum level set. Critics of this approach say that you may end up with either too many or too few products.

JIT Inventory: The just-in-time (JIT) inventory management strategy lines up the raw material order from suppliers with the production schedule. You decrease waste in the form of inventory cost because the goods are onsite only as needed. JIT can be a step in Lean manufacturing by slightly requiring JIT to incorporate what the customer wants in each product manufactured. The risk with this method is running out of stock due to inefficient suppliers, but supplier relationship management can somewhat mitigate this risk.

Two- or Three-Bin System: A two- or three-bin system involves two containers of the same stock item. When one container becomes empty, you use the second container (the backup), which then identifies the reorder point (ROP). The ROP is when inventory gets down to a level that initiates stock replacement activities. The problem with a method this basic is evident in situations where there are big or fast orders. You may never be exactly sure how much product is in stock at a given time, so you may not be able to predict whether you can fulfil a large order or quick, successive orders.

Fixed Order Quantity: In a fixed order quantity rule, you may only order a specific amount of an item at one time. With this rule in place, reorder mistakes, storage space issues and unnecessary expenses are kept to a minimum. You may link fixed order quantities to automatic ROPs.

Fixed Period Ordering: In a fixed period ordering rule, you link the replenishment of specific items to a particular interval. In this case, the order quantity is always different to compensate for customer demand.

Vendor-Managed Inventory (VMI): In this method, it’s often the sales representative that manages the stock on specific products, noticing and ordering what needs replenishment. For example, a beverage company representative who performs deliveries reviews the stock and space available for their products in the store and replenishes it themselves.

Set Par Levels: When inventory drops below the par levels, your software should signal you to order more. Par levels vary by product, relative sales rates and the time to restock and require research and sound decision-making. Par levels change over time and must be reset at regular intervals. On the positive side, having minimum levels makes your business more efficient and flexible. When new products hit the market, you can purchase them because your funds are not completely tied up in existing inventory.

Further, storage costs are lower, and if your business moves fast, having only the minimum levels of stock may be more suitable. Some challenges you may face include possibly running out of stock, when ordering the minimum could be more expensive and the variability of how well your suppliers can deliver products quickly and efficiently. You should also have a safety stock alongside your minimum inventory. Safety stock is the stock you keep in excess in case there are delays in delivery. You use this stock only in case of emergency.

Stocking Methods Compared

| Stocking Methods | How | Who/When |

|---|---|---|

| FIFO, LIFO | Categorise current sales as going either FIFO or LIFO | FIFO - industry where goods are perishable, especially LIFO - any business with rising costs (for accounting) |

| Fixed order quality | Only specific quantity of item can be ordered | When the industry costs are stable |

| Fixed period | Item only ordered at a certain time | When demand fluctuates |

| Vendor managed inventories (VMI) | Vendor manages your stock | When the market demand fluctuates and the goods are perishable |

| Min-max | Set min and max quants for each item | New or small businesses who want to keep it simple |

| Just-in-time (JIT) | Goods only onsite when they're needed | More experienced practitioners and businesses comfortable in their industry |

| 2-3 bin system | 1 container always in use, 1-2 containers always full | For small parts that are small volume that can be resupplied quickly |

| Set par levels | Order when minimum of items reached | All businesses |

7 Top Inventory Control Best Practices

The most effective inventory control methodology can vary between companies. Whichever methodology you choose, it should be clear to employees and have well-defined policies and procedures. If you use software with your methodology, look at systems that boast the key features your company needs, not just a one-size-fits-all package. Organisational control starts with labelling items, whether via SKUs or a more complex system. Quality control requires having quality standards and policy for staff to follow.

Choose a Management Improvement Methodology: Management improvement methodologies involve more than just inventory control. You can improve your business, from top to bottom, with a management methodology that you commit to. Examples include Kaizen, Lean and Six Sigma.

Optimise Purchasing Procedures: One of the hallmarks of proper inventory management is ensuring that you use data and forecasting to control your purchasing procedures. This also includes identifying items by monitoring customer demand, removing obsolete stock and adjusting safety stock and reorder points.

Manage Supplier Relationships: It is critical to manage supply chain relationships well because you can often head off and solve problems by working closely with suppliers. For example, suppliers can offer your business a negotiable minimum order quantity, take back products that are not selling and help you quickly restock when sales accelerate for a specific product.

Create Automated Reports: Since inventory control and management systems produce massive quantities of data, businesses need to find ways to analyse, report and use this data. Many systems automatically generate reports for inventory status, stock logs, reconciliation, historical stock, aging inventory and inventory financials. Further, companies should decide at what point along their supply chain they should share these reports, so suppliers can adequately prepare.

Conduct a Risk Assessment: Problems regularly crop up in businesses, whether you have an unexpected sales spike, a cash shortfall, not enough warehouse space, an inventory miscalculation, slow-moving products or discontinued products. Prepare a risk assessment matrix to determine what your worst risks are and how you can address them when they occur.

Regularly Audit: Conduct regular audits to ensure that your actual stock and reports line up. There are three ways to perform an audit: physical goods, spot checking and cycle counting. A physical inventory requires counting all your inventory and should be performed at least annually and often at the end of the year to line up with income tax reports. Spot checking is when you choose a product or two at a different time from the full inventory, physically check it and compare it to what is in your documentation or software system. Problem or fast-selling products are ideal for spot checking. Cycle counting spreads out the reconciliation throughout the year. Each product has its audit period, but you should check high-value items more often.

Selective Inventory Control (Forecasting): Many techniques fall under selective inventory control and management or forecasting, such as ABC analysis. In this form of analysis, you classify the inventory with one of the following: usage value, procurement source, procurement difficulty, seasonality, unit price and rate of consumption. Choose a formula based on the relative importance of each classification and how much it affects the stock.

Tips and Expert Advice for Getting Started With Inventory Control

Fully exploring the intricacies of inventory control procedures and theory may be a lot for some businesses. The tips below can help you identify what you need to do before implementing a new inventory control process:

A Good Inventory Control Plan Has Several Key Essentials: Purchasing a software system that addresses your warehouse stock is not enough. A good inventory control plan addresses your orders from production or purchasing to selling the items and ultimately removing them from your books. An inventory control program should account for things like reducing wasted warehouse space, ordering supplies using a forecasting formula and setting up vendor relationships.

Plan First, Then Execute: Any manager worth their salt will tell you that inventory management and control are continuous and do not live just at the warehouse level. You should continually update your plan, then put it into practice. You should be tracking metrics and updating your forecasts for future months weekly and making changes to your stock management planned as needed. You may also be required to change your inventory management plan based on world events.

Ensure You Always Have Critical Stock: Whether it’s machine parts or an item that is the backbone of sales, determine which stock is critical, and ensure those items never go out of stock. For this, you should have an inventory control process in place.

Carefully Review All Shipments: A key point of inventory loss occurs when your business initially receives an item. Closely review packing slips and products for any damage.

Appoint the Right Inventory Management Team Members: Staff buy-in is crucial, but make sure those assigned to own the inventory control processes are the right people for the job. Math should be among their strengths, and they should have time to perform the task correctly. Ideally, your inventory management team includes people that touch each stage of the process, from warehouse managers to procurement specialists to pickers on the floor. Smaller businesses should consider including all managers and some front-line staff representation.

Group Like Items: As much as possible, group like inventory in the same areas. Further, unique products should have a single storage location.

Find the Balance Between Inventory Costs and the Benefits of Having Stock on Hand: Developing a truly effective inventory control system relies on finding that right balance between the cost of making and storing product and avoiding stockouts. Your business’s money is tied up in that stock. Fortunately, getting to know your business enough will enable you to choose the right methods and forecasting techniques. You are looking to determine the total cost of your stock, including factors like warehousing costs and perishables, and weighing that against the demand and the cost of stockouts to give you the right balance

Look at Other High-Level Plans: If you do not have positive control over your inventory, you probably need to address other areas of your business. Do you have an adequate quality management plan? Have you looked at your facility management plan lately?

Choose a Scalable System: It is tempting for small businesses to order software systems that are one-size-fits-all or, conversely, free or low-cost. Cloud-based systems can grow with a business and provide the analytics you need to continue your business’s growth.

Your Software Is Only as Good as Your Processes: Software cannot solve bad processes, just automate them.

Have a Backup Plan: No matter how high tech the software or well thought out the process, ensure that your business has a backup plan for power outages and theft. Cloud computing is always a better option than a local server.

Control Stock With How You Sell It

You can also control stock with how you sell it. In some cases, the stock is not even a part of your onsite inventory, but you can still control it. Here’s how based on when or how you sell your products:

Bundling: Combining goods or services to offer the customer extra value for one cost is called bundling. In inventory control and management practice, bundling is a way to move aging inventory. For example, you include a surprise free gift or offer a reduced price on another item based on a purchase. These techniques also improve your customers’ experience.

Rolling Inventory: When inventory is rolling, instead of storing goods inside a warehouse, managers leave it in the truck trailer and store that trailer in the warehouse parking lot. A driver can hook up the trailer when the stock is needed and drive it to the retail store. Warehouse employees never touch the inventory.

Drop Shipping: Also known as cross-docking, drop shipping is when a manufacturer or supplier directly ships its products to customers on behalf of the retailer. The retailer never has the product in stock and never handles or sees the product. These businesses mostly work via internet sales.

Consignment Inventory: This business arrangement occurs when a company gives its goods to another company or storefront before they pay for them. The storefront or company pays for the products once it sells them, for an agreed upon percentage of the sale price. This arrangement can be an excellent situation for small businesses that are selling the products because their cost of ownership is minimal.

Backordering: When a company decides to take orders and payments for products that are not in stock, they are taking backorders. For a small number of items (one or two), it is easy to process the order and inform your customer with a forecast of when you will fulfil it. Further, the higher the value of the item, the more patient your customers will be with backorders. Problems mount, however, when the backordered products start to multiply. It is not recommended that small businesses whose products are generally stocked on-site mix with many backorders. Positive reasons to offer backorders include increasing cash flow, adding some flexibility for small businesses not capable of handling the logistics and lower holding and overstock costs. Challenges of backordering include possibly disappointing customers, longer fulfilment intervals and other logistical requirements.

Methods to Sell or Store Stock Compared

| Stock Control Methods by Selling or Storing Techniques | How | Who/When |

|---|---|---|

| Consignment Inventory | Payment after another business sells your products | Retailers of big-ticket items, low cash flow |

| Bundling | Combining goods for a discount | To impress your customers, use up obsolete stock, for discounts |

| Drop shipping | Manufacturers ship directly to customers | Businesses with no warehouse space, internet businesses |

| Rolling inventory | Goods never enter the warehouse | Fast-moving products, evergreen products |

| Backordering | Taking orders before the goods are produced or purchased | High demand or high-value products |

Forecasting for Inventory Control

Instead of using a manual method to reorder, look at ways to mathematically forecast what is in stock or when to order. These methods can include categorising your stock, such as in the ABC method, but mainly show what you currently have in store:

ABC Analysis:

This method of supply chain forecasting divides all on-hand inventory into three distinct groups. “A” items are those of high value and low sales frequency. The budgetary impact of these items is significant, but their sales are not predictable. “B” items are those of moderate value and moderate sales frequency. “C” items are those of low value and high sales frequency. These items require less oversight due to their lessened monetary impact and constant turnover. Using these delineations for inventory helps you prioritise by separating out products that need more attention than others. Forecasting done with ABC analyses calculates the number of stock available based on this delineation. Additionally, storage and packing locations can be set up to reflect these delineations.

Reorder Point (ROP) Formula:

The ROP formula mathematically tells you the right time to order or produce more stock. Using existing information, calculate the sum of your lead time demand and safety stock. You may need to know the reorder lead time alongside this formula, which is the time between placing an order and when you receive it. You must account for the lead time when calculating order timing. The formula for reorder point is:

| ROP | = LTD + SS = 100 units + 50 units = 150 units |

Let’s say that Ava has to calculate the ROP for the liquid bandages her company manufactures in its facility. She calculates the safety stock (SS) for this product at 50 units.

SS = (Maximum Daily

Usage x Maximum Lead Time) - (Average Daily Usage x Average Lead Time

Days)

SS = 50 units

She then calculates the Lead Time Demand (LTD) for that product.

LTD= (Average Daily Usage x Average Lead Time Days)

Her manufacturing department uses 20 units of raw materials per day, and it takes about five days for a reorder of those materials to arrive.

Using this information, she can calculate the ROP:

| ROP | = LTD + SS = 100 units + 50 units = 150 units |

If stock for liquid bandages falls below 150 units, then Ava must place a reorder.

Follow this handy chart to calculate your ROP:

| Product Name | Liquid Bandage, Generic, 16oz |

| Product SKU/Code | S123-LBT-16 |

| A. Curent Stock Level (units) | 30 |

| B. Lead Time (days) | 3 |

| C. Max Daily Usage | 20 |

| D. Max Lead Time (days) | 5 |

| E. Average Daily Usage | 10 |

| F. Average Lead Time (days) | 3 |

| Reorder Point Formula = (B * E) + ((C * D) - (E * F)) |

= (3*10) + ((20*5)-(19*3)) = 30 + (100 - 30) = 30 + 70 = 100 |

| G. ROP | 100 Units |

| Is A (current Stock Level) less than G (ROP)? | Yes - Reorder |

“Inventory management gets complicated very quickly, explains Dr. Pyke. “For example, a reorder point model has a trigger. So, the order fixed quantity is hopefully set up in a way that optimises the trade-offs involved (i.e. too much versus not enough). When I am helping a business, this is where I usually start their training. Moreover, problems often come in manufacturing when there are lags between the startups and process changeovers—for instance, an ice cream manufacturer changing over from chocolate to vanilla versus vanilla to chocolate. In the latter example, going from vanilla to chocolate, there are fewer complications and problems. Also, chocolate covers over a multitude of sins! However, when you go from the more complex (chocolate in this scenario) to the less complex (vanilla) process, it can take longer and add unnecessary layers of complexity.”

Economic Order Quantity (EOQ):

The EOQ determines the optimal amount of inventory you should buy or produce to make the costs of ordering and storing minimal. This formula is useful for when the demand, ordering and holding costs are consistent over time. You can modify the EOQ formula to compensate for different production levels or order intervals.

| EOQ | = √2DS/H, where, |

| D | = Demand in units per year |

| S | = Per purchase order cost |

| H | = Holding cost per unit, per year |

What EOQ Means

Let’s say that Ava wants to know the optimal number of size 12 glass bottles she wants to have in-stock for production. They are quite costly to purchase and store, so she must calculate the EOQ. Ava’s production team uses 1,000 size 12 glass bottles annually. It costs her firm about $3 per year to hold that bottle in inventory, and the fixed cost to place an order is $5. Therefore,

| D | = 1,000 size 12 glass bottles |

| S | = $5 |

| H | = $3 |

| EOQ | = √2 * 1,000 * $5/$3 = 33.3 (rounded) |

The ideal order size to minimise costs and meet customer demand is a little more than 33 size 12 glass bottles. Now that you have the ideal quantity, you can also use the ROP formula to determine the perfect timing to order these size 12 glass bottles.

Follow this handy chart to calculate your EOQ:

| Product Name | Size 12 glass bottles |

| Product SKU/Code | GB-12-THFG |

| A. Demand in Units per Year | 5,000 |

| B. Per purchase order cost | $5.00 |

| Economic Order Quantity Formula = √(2 * A * B)/C |

= √(2 * 5,000 * $5)/$3 = √5,000 / $3 = √16,666.6 = 129.1 |

| D. EOG | 129.1 units to order each time |

Supply Chain Inventory Control

There are some options for controlling your inventory along the supply chain. Whether you are on the production side or within the warehouse, these techniques can help.

Supply Chain Inventory Control Techniques

Batch Control: To control inventory you are producing, you can execute batch control. This method produces goods in batches sized to ensure that the right amounts of components are available to produce the required number of the finished product. Batch control is especially useful in concert with methodologies such as Lean manufacturing and just-in-time. Batch control procedures save money and resources.

Third Party Logistics (3PL): Some companies outsource portions of their supply chain, such as in their warehouse, distribution or fulfilment services. Outsourcing may occur at certain times of the year, such as during the holidays. 3PLs turn over employees constantly, especially when they only hire them seasonally. These inexperienced employees can account for a significant amount of lost or missing inventory.

Bulk Ordering and Shipping: One way to manage costs is to order items that you consider evergreen in bulk. You can also ship evergreen items in bulk at a discount. Companies lay out more money in advance, but since the items sell quickly and steadily, the risk is low. Bulk stock is easier to manage because of the product consistency, making the management costs lower. Manufacturers offer a discount when ordering multiples of the same product, making the products cheaper. This option may be suitable where the demand is difficult to predict. However, bulk ordering means higher storage costs, is challenging for perishable goods, can lead to obsolete stock and ties up capital.

Stock Quantities: How Much to Keep

The type of stock (raw, unfinished, finished or consumable) you have can also determine how much you should keep on hand.

For raw stock, look at the following factors:

- The reliability of the supplier and alternate sources of supply

- Whether you produce and deliver the components in batches

- The predictability of demand

- Bulk discounts

Unfinished stock, also called work-in-progress (WIP), costs you in storage space but is often beneficial. You can add an extra level of protection to your production with unfinished stock. For example, if you have a machine in the middle of a process that is at risk of breaking down, you can pull the unfinished stock to bypass that part of the process.

Keep extra finished stock around when you identify a product’s demand or when you are confident that your batch productions are adequate. You would also naturally have extra finished stock around when you are completing a large order.

How much consumable product stock you should keep around also depends on the reliability of your suppliers. If the demand for those products is well-known and steady, you may want to keep extra. Further, if you expect price rises or get a significant discount for bulk buying, having additional consumable stock is acceptable.

Inventory Control Policies and Processes

Inventory control starts the moment goods enter your organisation, whether through the front door or via a receiving dock. Developing standard operating procedures (SOPs) can help everyone understand their responsibilities related to stock. SOPs are step-by-step instructions that define routine activities.

What to Include in an SOP

In the case of inventory control, the SOP should, at a minimum, address:

- Receiving goods and supplies

- Storage and tracking

- Inspection dates and rotation

- Security

- Shipping

If you are developing new SOPs, clearly define policies and processes, and ask staff members (especially new ones) to review them for understandability. Additional tips for inventory control policies include:

Separate Administrative Inventory Control From Accounting and Finance: For security purposes, the staff who handle the administration of inventory control should not be the same personnel who perform stock controlling duties in finance or accounting.

Prioritise Accurate Inventory Counts: Problems occur when trying to fulfil an order with an unknown or inaccurate amount of inventory in stock. Inventory accuracy is a higher priority than order fulfilment.

Choose the Right Tools: Before drafting your processes, determine what risks are inherent and acceptable in the type of tools you choose. Whether you use dedicated software, RFID tags or spreadsheets and bins, define your systems first.

Perform Continuous Improvement: To ensure continuous improvement, you must include it as part of your SOPs. Even a short section on the expected intervals for review provides a place for staff to start.

Consider How Often You Need to Conduct Stock Counts: There are three distinct ways to conduct stock counts: periodically, perpetually and a combination of perpetually and periodically. Decide on the intervals, and write them into your SOPs.

Factor in All Equipment: As you write your policies, consider the tools available to set realistic expectations. For example, if you want your physical inventories completed over a weekend, determine if your employees should have scanners that expedite their work.

Determine, at a Minimum, Annual Stocking Policies: At the bare minimum, annual stocking policies should include the maximum and minimum levels, safety stock levels and optimum reorder levels. You should also calculate your average inventory levels to help set these policies.

Prepare an Annual Inventory Budget: Before buying any inventory, and at least once a year, determine your annual inventory budget. This estimate is the total cost of ownership of the goods for the year, including the costs of materials, holding, fixed operation, logistics, redistribution and any miscellaneous items.

Basic Invoice Control Policies

Effective invoice control policies should inform staff about how your business invoices customers, including the schedule, forms and procedures. Developing reliable basic invoice control policies and procedures ensures you collect the hard-earned income from your products or services. Invoices are typically sent after order fulfilment. Your invoice policies can be templates and should be clear and simple so that staff can follow them without many issues.

The invoice types you need to control are:

Purchase Orders: Before processing an order, clients or sales staff submit purchase orders. These documents should be completed and signed by the customer, ensuring that all details are accurate.

Order Receipts: Policies around an order receipt should reflect the set of checks you perform upon delivery of a product. These checks should kick off invoicing and include the shipment tracking numbers and receipt paperwork.

Invoicing Processes: Templates are ideal to use for invoicing, especially if your software automatically creates them. Policies around invoicing should ensure the purchase order number, invoice date and include all the required payment details.

Software: If your customer base is large or growing, consider investing in invoicing software. Create policies that help support the development of a template, and ensure the software tracks and archives all transactions. Software can also make generating unpaid invoice reports more efficient and straightforward.

Past Due Payments: Inform all customers of your late payment or nonpayment policy. Be flexible, but ensure that these documents reflect the consequences. For example, explain grace periods and procedures about who follows up on tardy invoicing and what leeway they have so customers can make their own decisions about paying an invoice late.

Key Performance Indicators in Inventory Control

Key performance indicators (KPIs) are metrics that demonstrate how well portions of your company are functioning and how well you are achieving your key business objectives. KPIs are also useful for comparing your business to others in your industry. In inventory control, KPIs can help identify pain points and why you are losing money. If you are having stockouts, you will want to fix them so you can keep customers. You will want to look at your long-term and short-term goals using KPIs. Therefore, certain KPIs make sense to run regularly. For example, a stock-to-sales ratio is one KPI that can track forecasting:

Stock-to-sales ratio = (Beginning of month stock (BOM) / the month's sales)

Another KPI is sell-through-rate (STR), which helps retain customers. Use the STR as a metric to identify how long a product is in stock, if you need to reprice it and when to reorder. This metric is often compared to the inventory turnover rate, which has a longer period to calculate (often a full year). The sell-through-rate KPI compares stock received through a supplier to determine how much you sell monthly:

STR = Sales / BOM on hand x 100

Average inventory is a KPI that helps you understand how many products you are storing over specified periods:

Average Inventory = (Current inventory + previous inventory) / 2

Finally, the fill rate is a KPI that tells you how well you fulfiled your orders for single deliveries or for deliveries over a given time. This KPI is also called line item fill rate (LIFR), with the term “line” referring to the line on an order or manifest. The formula for LIFR is:

LIFR = (Number of items purchased / number of items sold) * 100

Another formula that determines LIFR is:

LIFR = (Number of lines the order fulfils / Total number of lines on order) * 100

A fulfiled order is complete when it is at 100%. For example, Jack Heinz orders four products:

| Ship To: | Today's Date: |

| Jack Heinz 566 44th St. Seattle, WA 98404 |

05/19/2019 |

| Product | Price | Quantity | Total |

|---|---|---|---|

| Seamless Carbon Steel Pipe | $339.00 | 2 | $678.00 |

| Copper Pipes | $5.73 | 4 | $22.92 |

| Plastic Trench Drain with Grate | $163.00 | 7 | $1,141.00 |

| Seamless Carbon Steel Pipe | $16.57 | 1 | $16.57 |

This company shipped lines one through three (the seamless carbon steel pipes, copper pipes and plastic trench drain with grates) on May 20, 2019. When the company ran the LIFR, it was noted as 75%, because there were four line items, of which only three were filled:

LIFR = 3 / 4 * 100 = 75%

The company shipped out the 90-degree threaded fitting on line four on May 24, 2019, bringing the LIFR to 100%. However, if your metric focuses on customer satisfaction based on fulfiling orders immediately, keep the metric for only the initial rate. The initial LIFR is 75% and undoubtedly provides more information than the final LIFR.

You can also calculate fill rates by case and value. When you expedite items outside the total shipment, you cannot count those non-expedited items as having been misses, and you should factor out the expedited items. In other words, your primary concern should be how your business fills orders regularly, not during exceptions.

Inventory Control Software

Manually controlling inventory has its challenges: It can be labour-intensive, difficult to share, prone to human errors, create excess paperwork you do not need and require continuous monitoring and fact-checking.

According to Dr. Pyke, one software solution doesn’t fit all organisations. He says, “there are systems that integrate with existing ERP (enterprise resource planning) systems. Some organisations have developed their own systems, taking their best thinking, and developing what they need exactly in-house. When I consult, I often help small businesses develop their own spreadsheets to start. One of the companies I advise is a large software company, and their software is excellent and can do major things for their company. These systems do exist for smaller companies, but there are also inexpensive options that can do just as good a job.”

4 Questions to Ask About Advanced Inventory Tracking Software

If you are starting to look at advanced software to track inventory, you will need to approach it carefully and thoughtfully. Choose inventory control software by answering four main questions:

What products and quantities of products do I need to

manage?

Your software needs will absolutely be different,

depending on what and how much you sell. For example, the software priorities are vastly

different for companies that sell food versus one that sells high-end electronics. Food

sales companies need software that can track expiration dates. Companies that sell high-end

electronics require software with security features and analytics that ensure their stock

does not become obsolete.

What are the critical features I need?

Some software systems will

integrate with existing systems, but some will not. It’s

critical to decide whether you need this integration or if you will build in the additional

costs to replace the software. Further, let us assume that your business has a trajectory of

massive growth within the next five years. In that case, select software that can scale.

What can I pay for software?

Software systems that target inventory

control can differ wildly in cost. Good salespeople can quote a price based on your

requirements. In that bottom line, include any other software that needs to change to

accommodate the new purchase and the cost to transition in staff time. Calculate the return

on investment (ROI) for every solution you review and how long it will take to recoup that investment.

What does software mean for staffing?

Determine if your current staff can

adapt to vast changes in how you do business. Then decide if you need to hire new staff with

different skill sets, reassign or retrain your current team. For example, if you employ many

low-skilled workers to count inventory, you may not need them with a perpetual inventory

system. Further, they may not be able to help you set up your new software or troubleshoot

it after installation. You may need to hire a staff member with technical software skills,

depending on the complexity of what you buy. If you can reassign loyal staff members to

other jobs or train them for the software, excellent. Otherwise, consider what your business

needs are first.

Getting Started With Inventory Control Software

To effectively control your inventory, you need item-level visibility—something software can provide if you use it consistently. In this case, consistent use means that every staff member uses it the same way every time they produce, sell or receive goods. Software can provide many things at your fingertips. For example, you always know what’s been sold and how fast, any unique offers and discontinued products. You have an electronic version of each transaction, which can include the part number, quantity and when and where you sold it.

Other advantages of having dedicated inventory control software include:

- Increase in profits

- Never have stockouts

- Barcodes and label track inventory

- No more inventory write-offs

- Quick and efficient auditing

- Saved time

- More system flexibility

- Quick information retrieval

- Built-in analytics for decision-making

To get started, look for the software with features that support your business’s needs and future.

When looking for new inventory control software, consider these features:

- Inventory optimisation parameters

- Tracking and forecasting tools to signal stock anomalies

- Tools that automate replenishment, including those that calculate the right stock levels

- Lead time management

- Safety stock calculations

- Cost management

- Logic to call out expired shelf-life and slow-moving products

- Support across multiple locations

- Back office software integration

- Automatic inventory monitoring

- Automatic batch controls

- Supplier data metrics

- Barcoding integration

- RFID system integration

- Multiple pricing for items, based on the customer

- Pricing in different currencies

- The option to update per item or per item group

- Multiple warehouse communication

- Quality control metrics

- Batch tracking

- Support for multiple users

When looking at any system, it’s important to keep in mind future needs and how technology can help. Dr. Pyke shares, “There is a big animal called forecasting coming. Everyone wants to predict everything underlying every purchasing decision that consumers make. Machine learning and the vast data amounts will only make the ability to forecast better. Taking advantage of that ability in a way that does not cost too much is the future of this industry.

“Blockchain in the supply chain is also up-and-coming. You do not need blockchain to be valuable, but the visibility to what is out there will improve. Over time, it will be interesting to see what is real and what is hype, but it all will have an impact, regardless. My advice is for businesses to sit on the sidelines for a bit and see what happens. Eventually, companies will be able to use it for improvements in inventory management.”

The Best Practices of Using Inventory Control Software

Whether you use a dedicated software system or spreadsheets, you still need to follow some best practices. Use whatever tools are on hand to optimise inventory levels.

Once you have inventory control software set up, follow these tips:

- Use platforms that talk to each other or have everything under the same system.

- Treat each item in your inventory differently; each SKU is different for a reason.

- Ensure your supplies are above board by using the available data.

- Use mobile devices when possible.

- Slot your inventory.

- Perform cycle counts and update the data in your system.

- Link all transactions to your software.

You should also ensure that you do not purchase something too complicated for what your company needs and that the software is worth the cost. If you don’t, it’s not just a waste of money, but you could end up needlessly frustrated. If your software comes with analytics capacity, though, make sure you perform the measurement.

If you bought or are looking to purchase inventory control software, use it to perform the following calculations:

- What products are selling and not selling

- Total inventory costs

- Inventory trends and sales data

- The inventory budget

How to Keep Your Stock Secure

Ensuring your stock is secure should also be top of mind when thinking about inventory control. Whether your concern is thieves and shoplifters or your employees, stock security affects the bottom line. To protect your goods from people who would steal them out your front door, identify which inventory is the costliest or the most desirable. For example, laundry detergent and razor blades are high-target commodities. Everyone needs them; they are sure to resell and are amongst the most stolen items in any grocery store. These products should be accessible to customers but placed in a high-visibility place if you have problems with theft.

You should fit expensive, high-end items such as computers and electronics with RFID tags that can add security. An alarm will sound if they are removed. Be sure to secure deliveries after their arrival. Before you log items into your system is a prime time for them to get lost or stolen. Dispose of any additional packing materials, so thieves do not get the idea that a delivery just took place. If possible, install closed-circuit television (CCTV), also called video surveillance, in your parking lots and other vulnerable locations to deflect potential theft.

An outside threat isn’t the only security concern you should have. Staff can steal, too. Train your team on the security systems in place and policies that address theft and its discipline. Many people are unaware of the toll theft takes on a business, including the costs of staff turnover and job security. So, train your staff to understand the true effects of stealing.

By setting up procedures that prevent theft, you can stave it off before it occurs. For example, staff who oversee stock should not also monitor the company’s financial records. Restrict access areas to personnel, and distribute responsibility. Consider whether all staff require access to every portion of your warehouse or every supply cupboard. Assign staff responsible for auditing to assist other staff with their supply needs. Regularly reassign staff to stock control to prevent collusion. Finally, consider if you’re using the functions in existing software to their best ability.

NetSuite Can Help Provide Visibility Into Your Inventory Control Process

Properly managing inventory can make or break a business, and having insight into your stock at any given moment is critical to success. Regardless of the type of inventory control process you choose, decision-makers know they need the right tools in place so they can manage their inventory effectively. NetSuite offers a suite of native tools for tracking inventory in multiple locations, determining reorder points and managing safety stock and cycle counts. Find the right balance between demand and supply across your entire organisation with the demand planning and distribution requirements planning features.

Learn more about how you can use NetSuite to manage inventory automatically, reduce handling costs and increase cash flow.

Award Winning

Cloud Inventory

Free Product

Tour(opens in a new tab)

Inventory Control FAQs

What is Inventory Control Process?

Inventory control process are the processes and techniques used to manage a business’s inventory. These processes help ensure inventory is stocked to the right levels, doesn’t expire or cost too much to store long-term, and is available at the right location and time.

What is an example of Inventory Control?

An example of inventory control is found at grocery stores and other businesses that sell perishable goods. Grocery stores work hard to ensure fresh food is available when customers want it, but don’t order so much that it goes bad on the shelf. With a warehouse business where perishable goods are not an issue, inventory control processes ensure high-demand products are readily available while lower-demand products are kept in lower supply.

What is the Purpose of Inventory Control?

Inventory is a major cost for businesses. In addition to the cost of the good, companies have to pay for storage and the related real estate, staffing, and utilities to keep those items available. Inventory control aims to optimise inventory so you’re not overstocked or understocked for any specific item.

What are the Four Types of Inventories?

The found main types of inventory are raw materials/components, WIP (work in progress), finished goods, and MRO (maintenance, repair, and operation supplies). Not all businesses carry all four types of inventories, but most businesses require at least one of these inventory categories.