Businesses wishing to do more to delight customers and gain an edge over their competitors can turn to the time-tested “value chain” approach for evaluating and improving their entire operations from the point of view of how they produce value for the customer. For example, by comparing the cost of each step of the production process to the value that gets added to a product at that step, businesses can shine a light on which steps are adding the most value that entices customers and offer the most bang for the buck.

analysing their operations using value chain thinking helps businesses pinpoint the exact activities that create their competitive edge or weakness so they can find the most crucial areas for improvement. By strengthening the individual links in the chain, the entire operation becomes stronger and more efficient — giving businesses more ways to beat out their competition.

What Is a Value Chain?

A value chain is a model that includes every step a company goes through — from the initial idea through delivery to the customer — to create a good or service. The value chain includes initial design, materials sourcing, manufacturing, marketing, sale, delivery and after-sale service. If that sounds a lot like a supply chain, it should. Value chains encompass more business activities than supply chains, but the main difference is their customer-focused point of view.

By studying the value chain, businesses can go step by step to find places to add values that customers look for when choosing where to spend their money. Not every business has the time or resources to perform a full analysis of its value chain — that would require a deep look at every step of production for every product — but many companies benefit from some value chain analysis on their highest-cost products, specific departments or anywhere they feel that a deeper look is needed before implementing efficiency improvements.

Key Takeaways

- The value chain is the series of steps businesses go through to create a finished product — from the initial idea to customer delivery.

- Value chains have two categories of components: the direct, or primary, activities needed to make and sell a good and support activities that affect efficiency of the primary activities.

- Businesses analyse the value chain to find ways they can increase customer value, either by reducing costs or differentiating their goods with features customers prize. Both approaches yield potential competitive advantage.

Value Chains Explained

The goal of the value chain model is to help a business gain an advantage over its competitors by increasing the value its products offer to customers. Once decision-makers or managers map out the steps in the value chain — either for one product or as a broad look at a company’s processes — they can analyse the costs and rewards of each step. That analysis then informs decisions about decreasing costs or increasing the value of a product in the eye of the customer. Lower costs can lead to higher profit margins or lower prices for the good, creating a “cost advantage” over competitors. And when customers view a product as more valuable than a comparable good, they are often willing to purchase it more often or pay higher prices, giving the business a “differentiation advantage”.

For example, let’s say a company’s value chain analysis highlights that its use of high-quality raw materials is driving up the cost of manufacturing. If the company’s goal is to gain a cost advantage over competitors, it can consider cost-cutting measures like changing suppliers or outsourcing costly parts of the process. If the business is aiming for a differentiation advantage, it can emphasise its high-quality materials and manufacturing processes in its marketing, positioning the product as a premium item — and charging a premium price. Both approaches to competitive advantage are possible when a business understands its value chain, and both have the same ultimate financial goal — higher profits.

Value Chain Origins

The term “value chain” was first coined in 1985 by Michael E. Porter of the Harvard Business School in his book Competitive Advantage: Creating and Sustaining Superior Performance. Its second chapter opens with the following lines, introducing what Porter called the “value chain”: “Competitive advantage cannot be understood by looking at a firm as a whole. It stems from the many discrete activities a firm performs in designing, producing, marketing, delivering and supporting its product.”

Porter goes on to emphasise customer value over cost as the crucial point of view from which to seek competitive advantage: “Value is the amount buyers are willing to pay for what a firm provides them … Value, instead of cost, must be used in analysing competitive position since firms often deliberately raise their cost in order to command a premium price via differentiation”.

Porter’s work showed businesses that focusing simply on reducing costs is only a fraction of the battle to win customers and stay competitive. By framing the customer’s opinions and preferences as a business’s primary focus, the value chain helps businesses differentiate from competitors and gain advantages in the market — even if they raise costs in the process. Customers are often willing to pay higher prices for products they perceive as higher value, whether that value comes from perceived higher quality, specific features or through marketing, customer service and sales techniques.

Porter’s value chain model is still used today by businesses to create and maintain competitive advantage.

How Do Value Chains Work?

The value chain breaks up a business’s processes and expenses into individual steps and weighs each one against the value it adds to the product. To determine how effectively value is added, many companies analyse sales data or employ surveys and market research to hear directly from customers about how they value products and what they think should be improved or added to a particular good or service. By analysing the value created at each step, businesses can more accurately price their products and keep their demand high — both for their premium products and their lower-value alternatives.

For example, if a business makes and sells musical instruments, its value chain would include the procurement of raw materials — like the wood used for the body of a guitar and the metal in the electronics — the entire manufacturing process, marketing, sales and support. For the guitar manufacturer Fender, higher-quality wood and more skilled craftsmen are employed to create the American-made Stratocaster compared with Stratocasters made in Mexico. By spending more on labour and materials in the United States, Fender increases the value of an American-made guitar and charges almost double the price of a Mexican-made guitar. While they share many components, the steps in the value chain that vary between the two guitars change each product’s value, costs and the price customers are willing to pay. By analysing sales data and surveying musicians, Fender can correlate the prices for both guitars with the value difference that customers “feel” between the two goods, maintaining demand for both options.

The Importance of a Value Chain

Value chain modelling is important for businesses trying to gain advantages over their competition, or maintain advantages they already have, because it helps them precisely identify where in their processes customer value is created. In his book, Porter described the importance of the value chain like this: “A systematic way of examining all the activities a firm performs and how they interact is necessary for analysing the sources of competitive advantage… A firm gains competitive advantage by performing these strategically important activities more cheaply or better than its competitors”.

Industries are constantly evolving through new technologies, processes, suppliers, marketing strategies and, most important, changing customer demands. Businesses seeking to stay ahead of the curve need to evolve alongside customers’ ever-changing wants and needs by regularly analysing and improving the value that their products offer. They can do this through studying and optimising steps in the value chain. If a business is the lone supplier or far ahead of the competition, finding advantages based on value differentiation may not be a top priority. In that case, the value chain can be analysed through the lens of supply chain best practises to find lower costs or higher productivity, which increase margins.

Components of a Value Chain

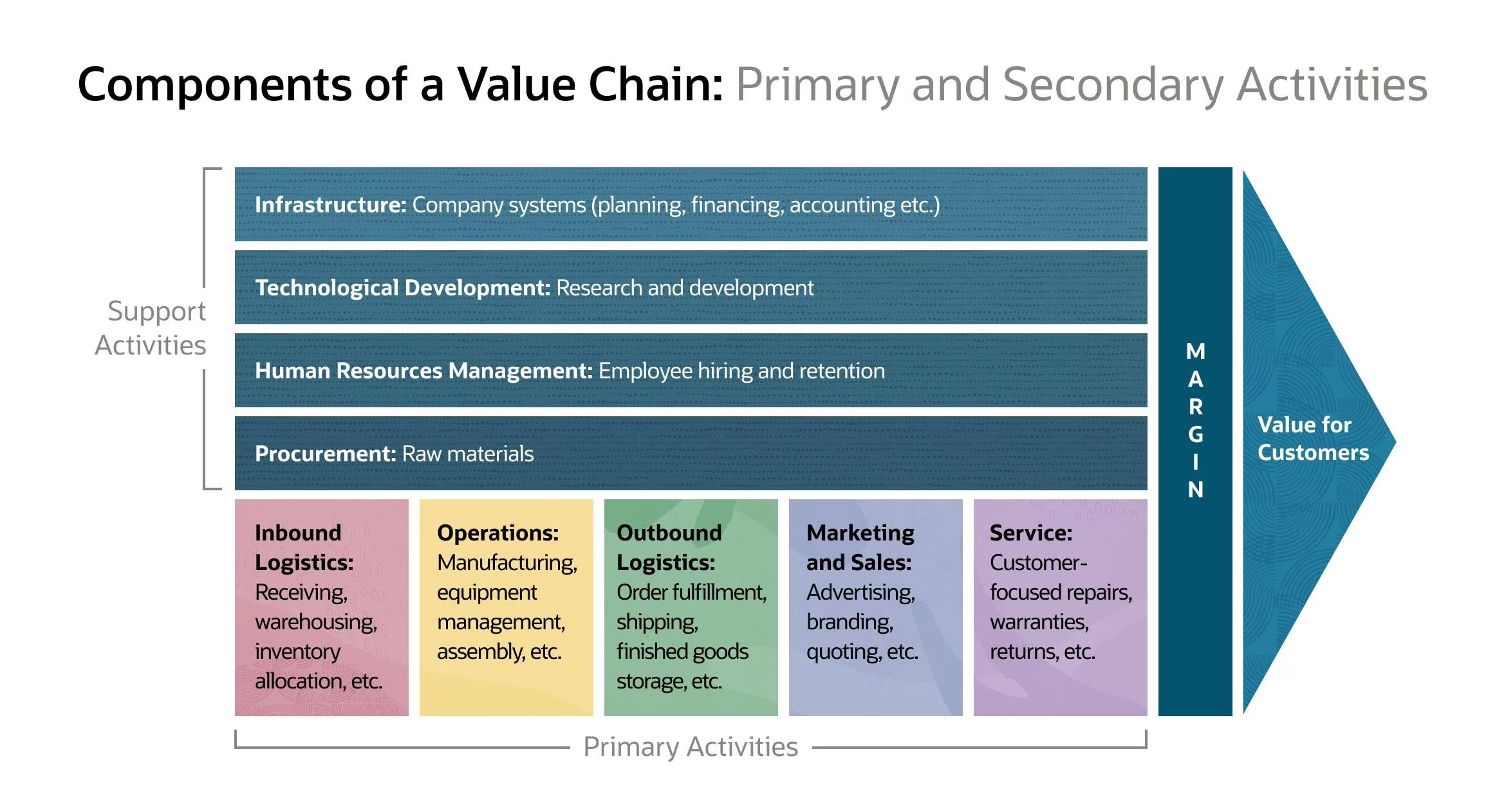

When Porter first wrote about the value chain, he split the components of the chain into two categories — primary and secondary activities — that are still used today by managers and analysts. Both are critical aspects of the value chain and contribute to the overall value of the company’s goods or services.

Primary Activities

Primary activities are made up of five steps that are directly involved in producing or selling a product and meeting external demands, the first three of which are roughly equivalent to supply chain management. These five steps are:

- Inbound logistics: This activity focuses on the relationship with suppliers and raw materials — sourcing, procurement, receiving, warehousing, inventory and storage. Inefficient inbound logistics raise the direct costs of producing goods and reduce profit margins.

- Operations: Manufacturing operations include all of the processes that take raw materials and turn them into the final product — including labour costs and machinery. An optimised operation can decrease order turnover time and reduce costs.

- Outbound logistics: Once a final product is manufactured, outbound logistics takes over through processes like distribution, inventory management and order processing. In the ecommerce world of two-, one- or same-day shipping, many customers value a quick and transparent outbound logistics system.

- Marketing and sales: Marketing and sales informs the customer about the good or service — and the value it provides — and provides a way for a customer to purchase it. It includes presale processes like quotes and pricing.

- Service: Many businesses provide services to improve or maintain a product’s value after the sale, like installation, repair, warranties, refunds, training or replacement/supplemental supplies. For expensive or long-term goods like appliances, many customers value reliable service above other features. Some companies implement reverse logistics to support customer returns.

Support Activities

Support activities affect how efficiently the primary activities operate. They are divided into four categories:

- Infrastructure: Infrastructure focuses on company structure and management. Planning, finances and legal systems contribute to a firm’s infrastructure and inform business decisions. Value-chain analysis and optimisation is usually performed by the managers, accountants and analysts who work in these infrastructure departments.

- Technological development: Many companies focus on research and development (R&D), but some view this activity more broadly than just R&D and expand it to mean any technology improvements. As described in Porter’s book, technological development “occurs in many parts of a firm … including such areas as telecommunications technology for the order entry system, or office automation for the accounting department”. Technology can be used to reduce costs and more efficiently utilise the workforce.

- Human resources management: Human resources (HR) management includes all of the activities related to hiring, training and retaining staff. A well-trained staff with a high retention rate can help quickly identify inefficiencies in operations and add direct value to customers through good service.

- Procurement: In the value chain, procurement, according to Porter, “refers to the function of purchasing inputs used in the firm’s value chain, not to the purchased inputs themselves.” These inputs are more than just raw materials — though raw materials rightfully get a lot of attention. They include machinery, laboratory and office equipment and buildings. Procurement provides the resources needed for most of the other activities — both primary and support — to operate and add their value to the product and the company.

Virtual Value Chain

The internet has shifted many customers and businesses from only physical goods and services to a mix of physical and virtual. That shift has created new types of “virtual value,” such as data and user experiences, leading to the virtual value chain concept. The virtual value chain focuses on these steps:

- Information gathering: Businesses first must collect as much information as they can on their customers, industry, the current state of the market and regulations to ensure that they are providing their goods or services effectively and satisfying customers’ needs.

- Organisation of information: Data collected by companies must be organised so it can be studied and analysed. Without proper organisation, the sheer volume of information captured can render it useless to the business, overwhelming even the savviest managers.

- Selecting what will be shared with customers: During this phase, businesses decide which information they will use to provide their product or service. For example, if a streaming service has collected enough data on the formats its customers prefer, this step will establish how the business’s content will be delivered to customers.

- Synthesising information: The virtual product is finalised and prepared for delivery to the customer. Formatting, virtual “packaging” and user interface are major aspects of synthesis.

- Information distribution: Finally, the product is delivered to the customer/user. To use the streaming service example, this is when the customer can finally watch a film. In an analogous physical value chain, this is where the delivery of a DVD would occur. Both physical and virtual value chains have the same goal — satisfied customers buying and using the product.

Value Chain vs. Supply Chain

“Versus” isn’t the best way to express the relationship between value chains and supply chains, since they largely overlap. The entirety of the supply chain is contained inside the value chain, so drawing a line between them can be tricky. The primary difference between the two is their focus. The supply chain is focused on the business’s needs, centred around how a company gets everything necessary to create its products or services. The value chain is focused on customers and what they look for when prioritising where they spend their money. Both are important for businesses to consider: The value chain and the supply chain should work hand in hand to allow a business to balance its needs and priorities with its customers’, creating value for both at every link of the two chains.

Value Chain Examples

2pure, a wholesale distributor based in the U.K., defines its core purpose as adding “value in ways which improve the experience of all participants in every interaction.” But to effectively add value, 2pure needed to evaluate its value chain to find areas for improvement. Starting at the warehouse level, optimising its distribution process cut its needed warehouse space by 40%. Further along the value chain, integrating previously disconnected processes and new technological developments — like a new website — reduced its sales staff’s time by 25%, increasing productivity. These value chain improvements led to a 95% increase in revenue without adding any additional staff.

Kentucky-based Accuserv grew out of an electrical company that found its customers — multifacility businesses, including national restaurants and hotels — had needs that were not being met by their current distributors. Seeing an opportunity to add new value to its services, Accuserv expanded to offer services like flooring, fixtures and HVAC, creating a managerial-adjacent role for the construction projects that many customers needed. By studying the values that customers were looking for — especially values that were not being met by competitors — Accuserv was able to show six straight years of double-digit growth, forging its own niche to deliver customers exactly what they needed.

Streamline Your Value Chain With NetSuite

Creating a value chain for every product or service may seem like a daunting task for a company with multiple products and/or services. But NetSuite Supply Chain Management makes it easier, giving businesses visibility on which areas can be improved by way of thorough data across their supply chains. NetSuite’s solutions help business managers monitor and analyse every step of production, from incoming materials from suppliers to tracking customers’ orders, ensuring that each step is adding value — for both the business and for the customer.

In addition, NetSuite’s software gives businesses accurate and real-time inventory, order and financial data to effectively plan demand and forecast sales, minimising over- and understocks. By integrating data from throughout an organisation, NetSuite gives businesses a big-picture view of the value chain, ensuring that each step is running smoothly and that each link in the chain is not only strong, but well-connected and working in harmony with the rest of the organisation.

The value chain has been an important model for improving businesses for decades. By framing the customer’s desires as the primary method for producing a good or service, the model leads businesses to increase the value of their products in two main ways — by reducing costs and by increasing their products’ appeal. Both goals can increase profit and give businesses an advantage over competitors while satisfying customers’ needs, making value chain improvements a win-win for both businesses and customers.

#1 Cloud ERP

Software

Value Chain FAQs

What is a value chain analysis?

Value chain analysis is a method for evaluating each step in a business’s process that adds value to a good or service. Each step can be optimised based on the needs and goals of the company and its customers.

What are the goals and outcomes of value chain analysis?

Companies can use value chain analysis to gain advantages over their competitors. This can be done by either reducing costs to lower prices and/or increase profits or by differentiating goods to increase their value.

What are the benefits of a value chain analysis?

A value chain analysis can give managers visibility on where a business’s costs are highest and where the most value is added to its goods or services. Value chain analysis can also give decision-makers insight into where efficiency improvements can be made.

What are value chain management and mapping?

Value chain mapping organises all the steps of a value chain to give managers more visibility into the processes and how they are interconnected. Value chain management is the process of business decision-makers using value chain mapping to effectively implement strategies and oversee the steps of the value chain.

What is an example of a successful value chain?

2pure, a U.K.-based distributor, made improvements throughout its value chain — including warehouse operations and sales — to increase its revenue by 95% without hiring any additional staff.

Why does value chain analysis matter?

Value chain analysis helps businesses successfully compete by showing areas where they can gain an advantage over competitors. Michael E. Porter, who coined the term “value chain,” defined it as a “systematic way of examining all the activities a firm performs and how they interact is necessary for analysing the sources of competitive advantage”.

What is a value chain with examples?

A value chain is every step involved with a business’s production, from the idea of a good or service to customer delivery and after-sale support. For example, guitar manufacturer Fender uses higher-quality raw materials and more skilled craftsmen during the manufacturing process to create the American-made Stratocaster guitar compared with Stratocasters made in Mexico. By spending more on labour and materials in the U.S., Fender also increases the value of an American-made guitar, for which it charges almost double the price of a Mexican-made guitar.

What are the types of value chains?

There are two main types of value chains. Physical value chains are used in the production and delivery of physical goods. Virtual value chains are used to deliver information or digital goods to customers/users.

What are the four components of the value chain?

There are four components of the “support activities” aspect of a value chain — infrastructure, human resource management, technology development and procurement. The five “primary activities” of the value chain are inbound logistics, operations, outbound logistics, marketing and sales and service.