Order management begins as soon as a customer places an order. For a small business, order management can be a relatively simple and manual process — a few orders picked from a modest inventory, manually packed and shipped to their final destinations. But for larger businesses with broad customer bases and a wide inventory, seamlessly navigating the order management process can be a challenge. For this reason, an order management system (OMS) is often employed to ensure customer orders are fulfiled accurately and efficiently.

What Is Order Management?

Order management involves the processes that start once a customer places an order, generally ending when the customer receives their items — unless there’s an error that requires opening a customer support ticket. Order management entails the entire behind-the-scenes coordination between people such as warehouse employees and managers; software, including order management, customer relationship management and enterprise resource planning systems; and partnerships, like third-party logistics and shipping partners. These components work together to fulfil orders as quickly and accurately as possible so that customers are satisfied not only with their products, but also with how the company handled their order.

Effective order management requires fulfiling orders without overwhelming the business’s capacity. For a very small business with limited inventory, this can sometimes be handled manually, via spreadsheets or even traditional pen and paper methods. But given customers’ rising expectations for fast shipping, manual methods are no longer sustainable for larger companies. Fortunately, order management systems are up to the task. An OMS works to increase the efficiency and accuracy of order management processes — and, consequently, benefit the company’s bottom line.

What Is an Order Management System?

An order management system (OMS) is software that helps streamline and track an order’s journey from start to finish, with the goal of fulfiling orders as accurately and efficiently as possible.

An OMS allows businesses to handle sales increases while meeting customers’ shipping and service expectations. In turn, this can help maximise profitability: Satisfied customers tend to return and/or recommend services or products to others.

An OMS usually offers features that facilitate processes within sales channels. For example, the system may include product information and availability, as well as a customer database with support information. An OMS may also assist with returns and exchanges, and some may offer integration with other business software to facilitate a businesswide flow of data. Furthermore, by tracking critical KPIs and generating fulfilment reports, an OMS can offer insights on which aspects of the order management process are working well and which may need improvement.

Key Takeaways

- Order management includes the business processes that begin after a customer places an order. It involves accepting and fulfiling the order, managing inventory and engaging in post-sales interactions.

- Effective order management is important because it has a direct impact on order fulfilment accuracy and efficiency and, therefore, customer satisfaction.

- Challenges of order management include the possibility of human error, fulfilment and inventory inaccuracies, and cost management.

- An order management system can improve the order management process by automating tasks and offering key business insights.

Why Is Order Management Important to Businesses?

The order management workflow directly impacts not only the daily tasks of fulfilment employees, but also customer experience — and, subsequently, how a business is viewed by its customer base. Here are some of the reasons why good order management practises are so important to businesses:

-

Order accuracy. Delayed shipments or incorrect products can be detrimental to a customer’s opinion of a brand. Good order management practises can provide a business with an added layer of control and visibility into each step of the process. When using an OMS, automation can greatly decrease the chance of human error when fulfiling orders.

-

Order fulfilment efficiency. Good order management practises consider how all systems and processes within the supply chain inform each other to improve efficiency — without sacrificing accuracy — wherever possible. For example, in an omnichannel environment, an OMS can automatically identify which fulfilment location is closest to the customer to shorten shipping times.

-

Inventory accuracy. Effective order management processes integrate with those of inventory management. Because a company must always keep tabs on inventory quantities to effectively fulfil orders, it must also be able to accurately calculate inventory turnover ratio to prevent losing cash due to overstock. This can be accomplished manually for small businesses, but larger companies may benefit from an automated OMS that can integrate with an inventory management system (IMS) to provide an immediate overview of inventory — even across multiple warehouses and distribution centres. Understanding the flow of inventory can help companies develop more accurate plans.

-

Cost management. As mentioned above, well-implemented order management processes may save money by enhancing efficiency and preventing overstock and stock-outs. However, efficient order management can also help reduce labour and shipping costs by helping workers make the best use of their time. For example, an OMS can automatically determine the most efficient ways to pick and pack a series of orders.

How Does Order Management Work?

Order management is a multistep process, and the more orders and customers there are to service, the more complicated the process gets. While every company will handle its order management processes according to its needs, the order management cycle typically includes every step from the moment a customer purchases an item to the moment it’s received — and sometimes after.

The Order Management Cycle

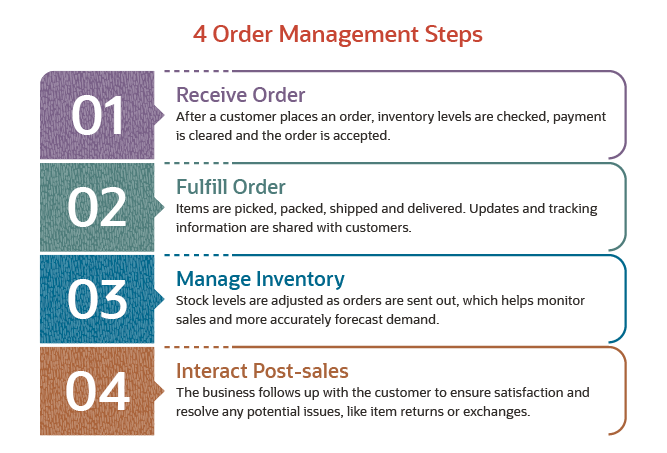

The order management cycle is the series of steps taken any time a customer makes a purchase. The process includes various moving parts and touches nearly every component of the supply chain, from manufacturing items to customer receipt. Regardless of a business’s size, capacity or industry, the basic steps of the order management cycle are:

-

Receiving the order. Accepting an order is the first step of the order management cycle. This can happen manually, or it can be automated. For example, with an OMS, accepting an order can happen in seconds without requiring an employee to check inventory and accept the payment. As long as the item is in stock and the customer’s payment method clears, the order can be placed, triggering the next step.

-

Fulfiling the order. Order fulfilment can be divided into multiple small steps. In small businesses, orders are usually manually picked, packed and dropped off at the shipping facility of choice. In large, omnichannel operations with various large warehouses, automation helps streamline the same “pick, pack and ship” process.

-

Managing inventory. After items are shipped to their destination, it’s crucial to keep inventory numbers in order. This can help a business more accurately predict demand and monitor inventory levels to avoid overstock or stock-outs. For example, a business that makes its own products can analyse its inventory data to help production managers forecast and plan more effectively — a step that can ripple out to the larger supply chain when a company must purchase raw materials or other components from its suppliers.

-

Managing post-sales. The last step for effective order management is following up with the customer for feedback. This can involve a simple email to ask how they like the product, or a short survey — either of which can provide valuable insight as to whether the company’s order management process is being handled effectively. This step can also include managing returns, exchanges or refunds.

Key Challenges of Order Management

Customer satisfaction can’t be achieved without delivering orders quickly and accurately. Since any error can be costly, it’s important that businesses prepare themselves for the common challenges faced when managing orders, such as:

-

Errors in order picking. Delaying a shipment or sending the wrong product to a customer can be a quick way to lose their trust. Doubling a shipment or sending out an incorrect number of items is a quick way to lose money. Good order management practises that utilise an OMS can minimise the chances of inaccurate shipments by eliminating the need to manually type out key order information, like SKU numbers and quantities.

-

Managing returns inventory. If a customer changes their mind or if an order error occurs, an item may end up being returned. The order management process should cover detailed standard operating procedures for handling returns. This can include taking measures to ensure that any items that are still sellable go back to inventory — and, equally important, making sure damaged items don’t end up back in circulation.

-

Maintaining inventory visibility. When ordering online, a customer trusts that the item purchased is available and will be ready for shipping as soon as possible. To fulfil the order and keep that customer happy, it’s vital that businesses can accurately view inventory status — especially in real time. Maintaining a tight grip on inventory management proves particularly challenging when there’s more than one sales channel or multiple fulfilment centres.

-

Minimising excess costs. Excess costs can stem from issues like poorly managed inventory or inaccurate shipments. What’s more, shipping costs can quickly add up if companies are not using the most cost-effective shipping methods. To counter excess costs, some businesses may consider partnering with third-party shipping and mailing companies. And for omnichannel businesses, making sure an item is shipped from the location closest to its destination can be helpful.

-

Abating complexity. As a business grows, it gains more customers, more inventory and more warehouses, all of which makes order management more complex. This increased complexity also can mean more opportunities for mistakes. An OMS — especially when combined with other key business solutions like an ERP, CRM or inventory management system — can help companies of all sizes streamline their order management processes and reduce the risk of errors.

5 Benefits of Order Management

Fortunately, good order management practises can often alleviate challenges related to shipping accuracy, inventory management and visibility, process complexity and excess costs. When implemented effectively, the benefits of order management include:

-

Increased customer satisfaction. If an order arrives correctly and on time, the odds of customer satisfaction increase. Of course, other factors like product quality and customer support are also vital, but meeting customers’ expectations of smooth and fast order processing and delivery is a key step toward satisfaction and retention.

-

Improved inventory management. Good order management processes call for a tighter grip on inventory data. This involves everything from ensuring accurate levels to avoid backorders to knowing the most efficient fulfilment centre to ship from in order to reduce shipping costs and delivery time. Better inventory management practises also can make it easier for a company to understand product flows — data that can be used for marketing and planning purposes.

-

Process transparency. Real-time view into each step of the order management process plays a key role in isolating problems and mitigating missteps and, therefore, processing orders more accurately. Customers also like to receive information regarding the status of their orders, such as shipment tracking. Sending out status updates can help assuage a customer’s anxiety — especially for big-ticket items — and improve their overall satisfaction.

-

Increased efficiency. For a business to fulfil orders as efficiently as possible, it’s necessary to streamline order management tasks and processes wherever possible. Following the same step-by-step order management process for all orders typically helps businesses optimise their time. What’s more, an OMS can automatically determine the most efficient processes on a case-by-case basis, such as employing the right order-picking strategy(opens in a new tab).

-

Cost reduction. Most of the aforementioned benefits can significantly improve a business’s bottom line. For example, shipping costs can be reduced by fulfiling orders from the nearest warehouse or distribution centre — a process that can be enhanced by an OMS, which can automatically identify the most efficient course of action. Good order management practises that incorporate an OMS can also help slash labour costs by automating routine tasks like order processing.

Optimise Order Management With an OMS

An OMS can benefit any company that regularly fills customer orders. After deploying an OMS, a business of any size may see improvements in its order management process — ultimately saving time and money, increasing the chances of a satisfied or repeating customer. The right OMS is the one that fulfils a business’s current needs, can integrate with your company’s current business technologies, and allows room for growth without the hassle of migrating to another system.

NetSuite Order Management, for example, offers the tools necessary for managing and scaling business. It automates and manages an order through its life cycle, from placement to post-sales customer service. This eliminates the need for manual order management while increasing accuracy and efficiency throughout each step of the process. NetSuite Order Management supports complex processes like split shipments and route planning when there are multiple sales channels. It also ensures accurate and updated recordkeeping, which can help companies more accurately plan. In addition, NetSuite Order Management can automatically generate detailed dashboards and reports that offer insights on how to meet or exceed customers’ expectations.

Customer satisfaction is one of the main goals for any company that sells goods or services. That’s because a satisfied customer is more likely to order again from your company, thus generating more revenue. Good order management practises streamline processes to boost efficiency when fulfiling an order. And when combined with order management systems, companies may be better suited to retain customers, thanks to greater order accuracy, quicker deliveries and more efficient customer support.

#1 Cloud ERP

Software

Order Management FAQs

What is meant by order management?

Order management refers to the stream of processes triggered when a customer places an order. It’s how a company handles the order after it’s been accepted and paid for, and it includes each step from accepting the order to managing post-sales customer communications.

What is the function of order management?

The function of order management is to ensure each customer not only receives their order in a timely manner but is left satisfied with both their purchase and their interaction with the company. At the same time, effective order management can help a business save time and money — especially when utilising an order management system.

What is order management in the supply chain?

Order management plays a critical role for all businesses that regularly fill customer orders because it touches nearly every step of the supply chain (the network of steps required to get a product to a customer). Specifically, order management includes the process of receiving and accepting an order; picking, packing and shipping the order; and following up with the customer to ensure satisfaction.

What are the elements of order management?

Though every business manages orders differently according to its specific needs, the typical elements of a good order management process include:

- Receiving and accepting an order. A customer places an order and it’s accepted by the business.

- Fulfilment. The customer’s order is picked from inventory, carefully packed and sent to a shipping partner that will deliver the order safely and in a timely way.

- Managing inventory. Inventory is updated, either manually or automatically. This step is crucial because it can help prevent inventory issues like stock-outs.

- Managing post-sales. The business contacts the customer to receive feedback about their order. This might include a short survey to see how the business did, or instructions for managing item exchanges or returns.